Roboter-Sanierung

Old Robots in Need of Care? We Can Help!

If your robotic equipment is not performing well, perhaps it needs a tuning. Our robot repair and optimization services restore robots (both the arm units and control cabinets) thorough cleaning, repairing and parts replacement services rendered by expert technicians and craftsmen. Refurbished robots look and work better and for longer.

UsedRobotsTrade is specialized in refurbishing robots. We have a standard process of reconditiong where each robot pass in order to delivery high standard of quality. We do not just clean them; we change the oil, repaint them with a help of professional painter and do the complete mechanical and eletrical revision by specialized technicians.

Our clients often ask us what we do for a revision of a used robot, so in this section, briefly, we explain what we do check, when we go through our inspection.

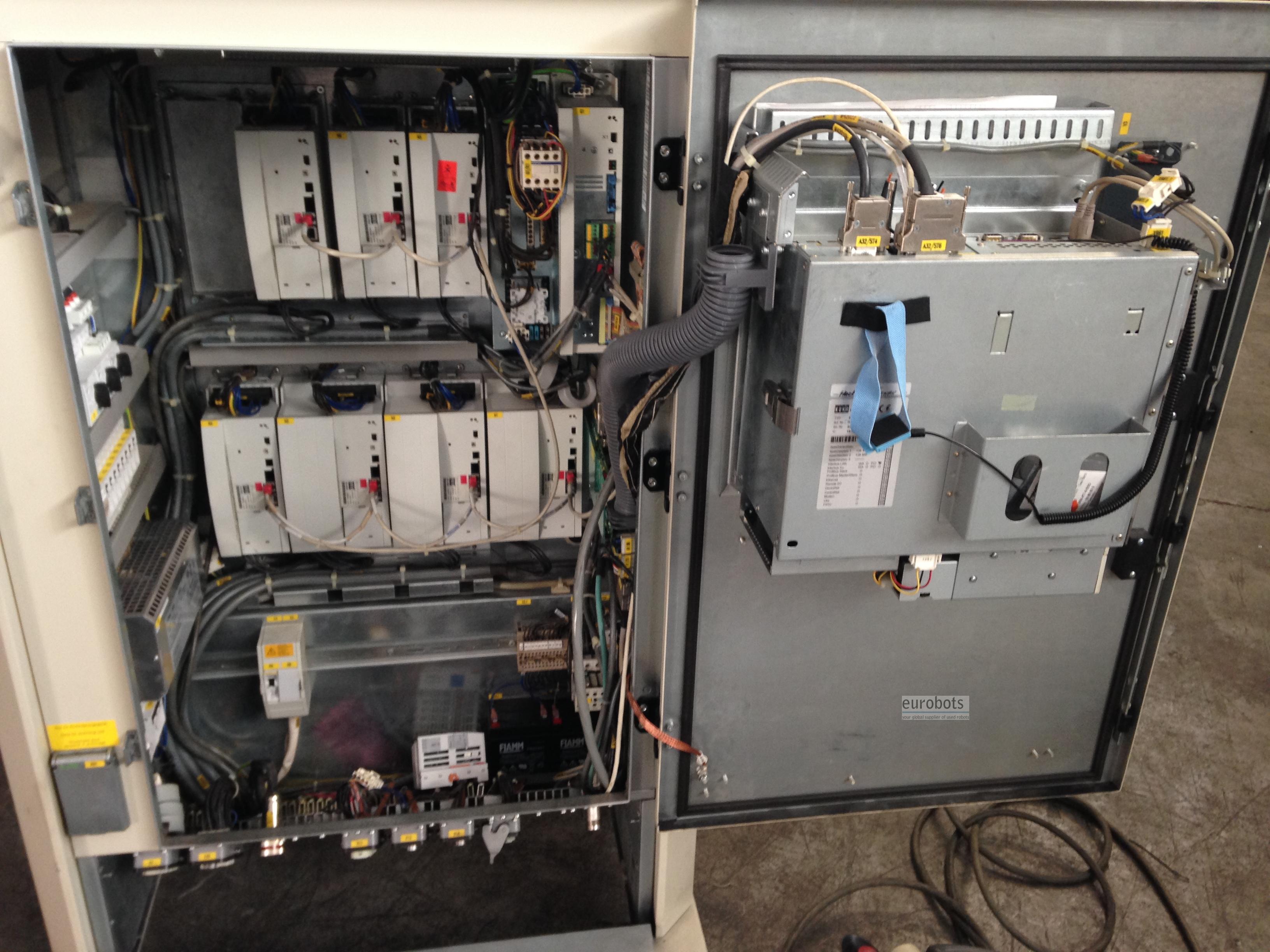

Control Cabinet:

- New configuration of the robot, if necessary

- Check the all surface

- Checking of the components

- Check and cleaning of the fans

- Check the filter

- Batteries tested or replaced

- Check cables functioning

- Teach pendant screen inspected

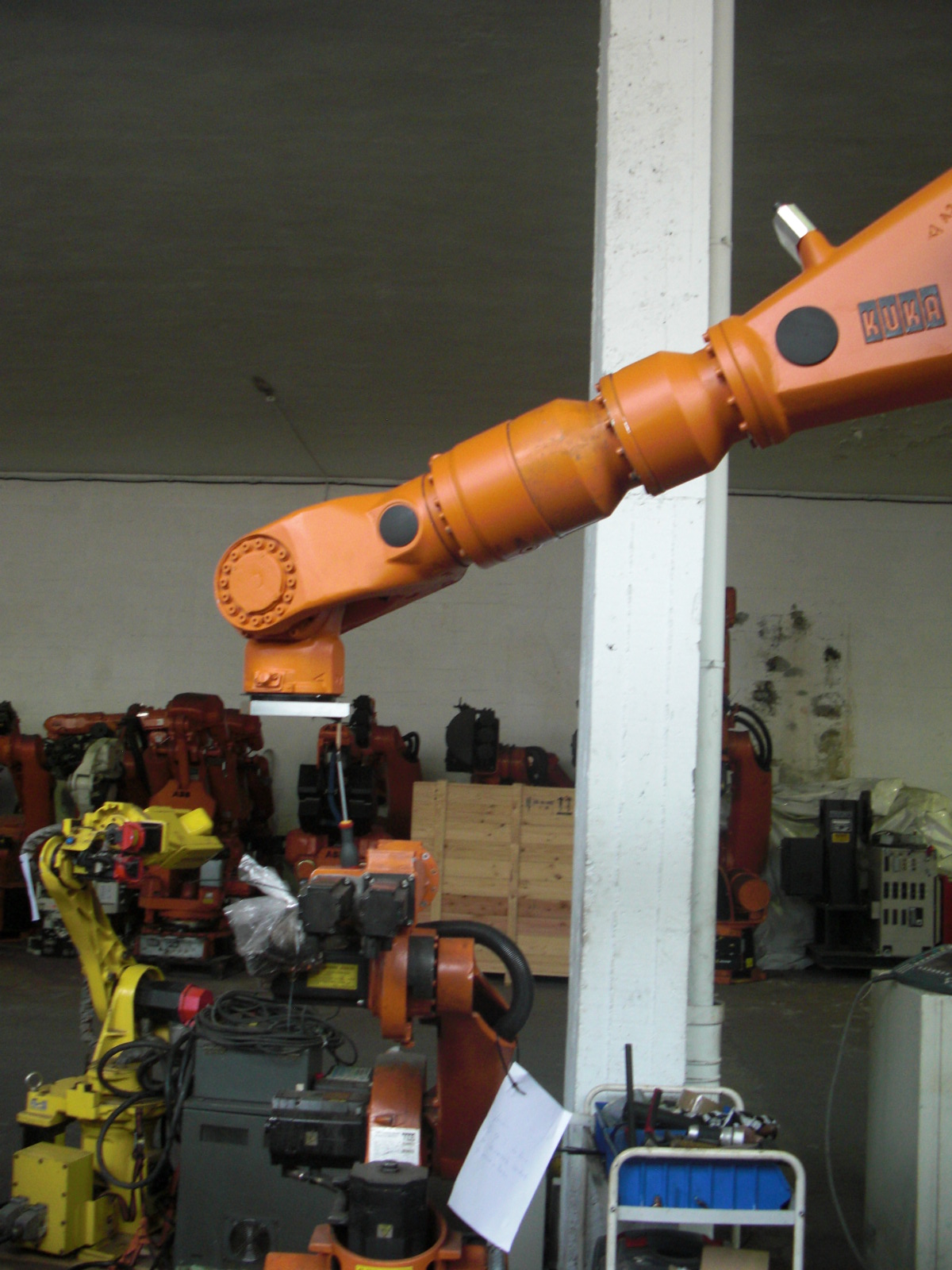

Robot Arm Unit:

- Oil or grease changed or replaced

- Check of the belts

- Inspection of any malfunctions in the wrist

- Check all the 6 or 4 motor axes

- Check Internal and external cables

- Check counter balance

- All the dirt is removed with special machines and products

- The robotic arm is fully painted with the original paint

- Take off the unnecessary cables

- Checking of the all connectors

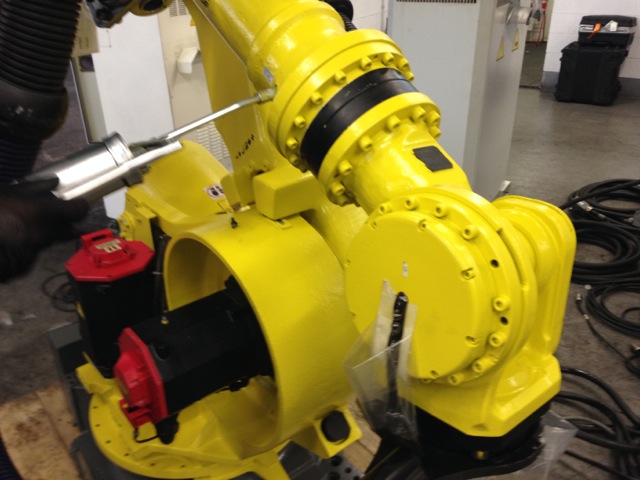

Painting Robots

In this station the robots are fully prepared for painting. We gather all cables with tape, all other parts are securely covered with high accuracy. Finally, robots are painted using high quality paint specifically manufactured for the industry sector.

Cleaning Station Dry eye CO2

The best way to clean dirty industrial machines is by using dry ice. This process is new and uses solid CO2 pellets “dry ice” to undergo the cleaning. It is often used for industrial work and the pellets sublimate convert directly from a solid blast pellet to a vapor (CO2) leaving no residue. The process is much better than sand blasting, glass bead blasting and other types of cleaning methods.

Testing Electrical and Mechanical components

We revise all the eletrical and mechanical componets in the robot’s controller, such as servodrives, mother bords, cables, eletrical funs,axis backlash and teach pendats. We have technitians that have more than 15 years of experience in the industrial machines sector.

Accuracy Station

Precion in robotics is the key factor in this field, therefore we always test each robot in its accuracy. We make certain that our machines will not have any backlash in the axis.

Oil change

Our technitians change the oil from the axis of the robots. We always make sure that the oil we use it is the approprite for each model type.

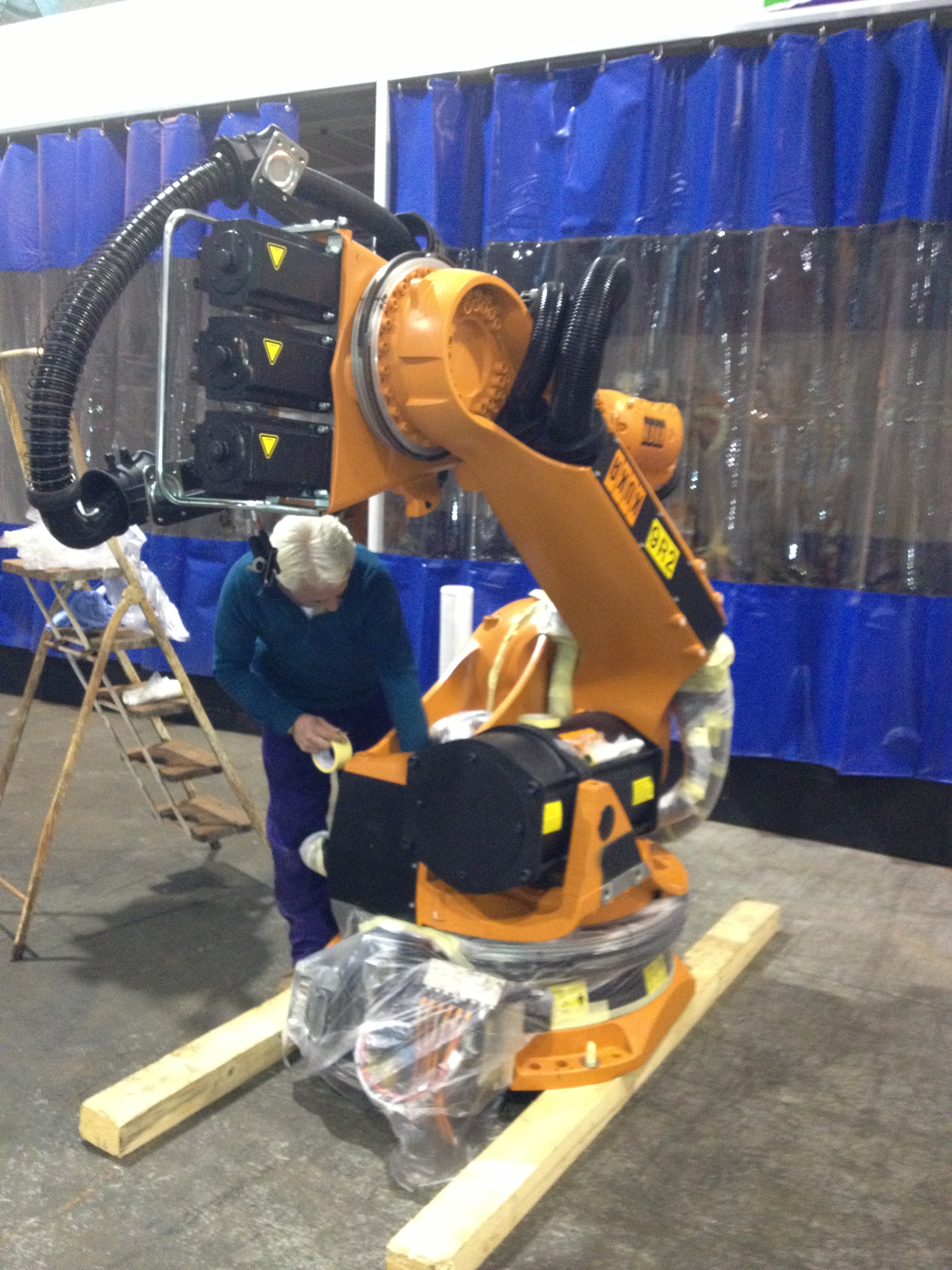

Packaging Station

For each robot we ship, we use new reinforced pallets. We cover each pallet with thin plastic foil in order to protect them from humidity and moist. We always make sure that the robots are safely placed in the tracks. Additionally, we provide the service of closed packaging where a smoked wooden crate is specifically built for each robot.